Application Solutions

For over 35 years, Careinder has provided custom-engineered reliability solutions across multiple industrial markets. Our innovative technologies increase reliability and decrease operational costs on a variety of rotating equipment.

Eliminate Constant Oil Leaks and Continuous Maintenance

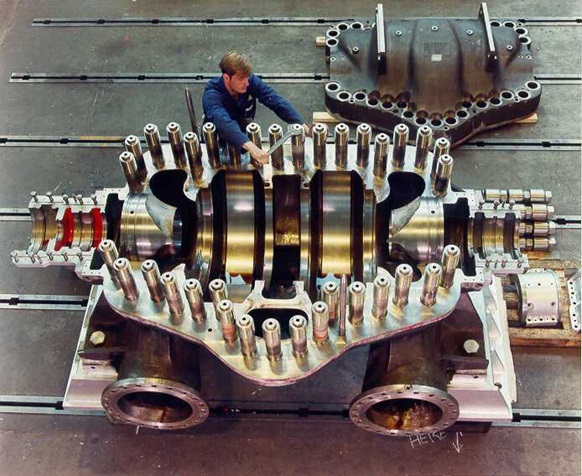

Gearboxes are a significant component in the industrial process and can be found within a variety of industries. Unfortunately, they can be unreliable and difficult to maintain due to constant oil leaks from ineffective sealing solutions. Lubrication loss is a primary reason for premature bearing failure on gearboxes, leading to unexpected downtime and high maintenance costs

Careinder offers multiple gearbox Bearing Seals designs that are perfect sealing solutions for the variety of gearboxes in your facility.

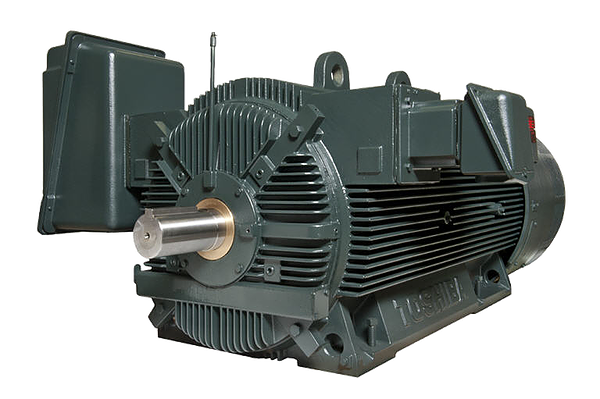

Increase Motor Reliability

Considering the significant investment many companies put into this equipment, it’s important to minimize downtime and take extra care during maintenance. Careinder creates a positive seal, eliminating contamination ingress and lubrication leaks.

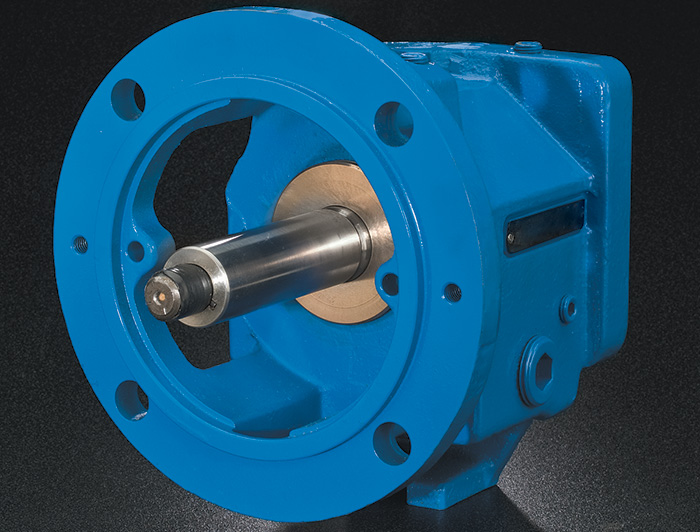

Maximize Pump Life and Reduce maintenance costs

Bearing failure is responsible for many pump failures. Contamination of the bearing lubrication is one the main reasons for the bearings to fail. Installation of effective bearing protection can prevent contamination of the lubrication and therefore significantly improve the reliability of the pump.provide a range of bearing protectors suitable for fitting to most pumps. The bearing protectors offer sealing up to IP69K/IP66, do not wear the pump shaft and require no routine maintenance.

No more water removal and Proven benefits for the long haul

Keeping bearings free from contamination on process steam turbines provides a unique challenge. Typically carbon ring seals are fitted to the turbine contain the steam. These seals wear with time allowing high temperature, high velocity steam to travel down the turbine shaft directly on to the bearing seals.

2. In Gearboxes

Gearboxes generate significant vibration, shock loads, and are contaminated with lubricating oil and wear metals.

· Higher Strength and Load Capacity: Bearing bronze has higher tensile strength and fatigue resistance compared to common brass. This allows the isolator to withstand the constant vibration, torsional forces, and mechanical shocks transmitted from the gears without deforming or cracking.· Excellent Compatibility with Steel Shafts: The compatibility between bronze and steel is outstanding. It has a low coefficient of friction against steel, minimizing the risk of shaft fretting or adhesive wear (gallling)—a common failure point with dissimilar metals.· Embeddability and Conformability: The slightly softer nature of bronze allows fine abrasive particles (from gear wear) to become embedded in the isolator's surface rather than scoring and damaging the critical steel shaft. This protects the more expensive and difficult-to-replace component.

3. In Turbines (Steam & Gas)

Turbines operate at high speeds, elevated temperatures, and require extreme precision and reliability.

· High Temperature Stability: Bearing bronze retains its mechanical properties and dimensional stability at the elevated temperatures found in turbine bearing housings much better than common brass, which can soften and lose strength.· Resistance to Steam and Condensate: Steam turbines create an environment prone to corrosion. Bronze provides excellent resistance to corrosion from steam and condensate, whereas brass would quickly succumb to dezincification.· Vibration Damping: The material properties of bronze are excellent for damping vibrations caused by high-speed rotation, helping to protect the bearings and ensure smooth, stable operation.

Bearing bronze seals are widely used in sealing industries

1. In Chemical Pumps

Chemical pumps handle aggressive fluids, slurries, and are often subjected to washdown procedures with corrosive cleaners.

· Superior Corrosion Resistance: Bearing bronze, with its high copper and tin content, offers exceptional resistance to a wide range of corrosive chemicals, including certain acids, alkaline solutions, and seawater. Common brass, with its zinc content, is highly susceptible to dezincification—a selective leaching of zinc that leaves behind a porous, weak copper structure—when exposed to acidic or high-chloride environments. This leads to rapid isolator failure and fluid contamination.· Enhanced Wear Resistance: Pump shafts can experience minor misalignment and vibration. The tin in bearing bronze forms hard intermetallic phases within a softer matrix, creating an ideal material that is wear-resistant yet has good emergency run-in properties. This reduces friction and groove wear against the shaft, extending seal life.· Non-Sparking Safety: Like brass, bronze is a non-sparking material, which is a critical safety requirement in environments where flammable vapors or powders are present.